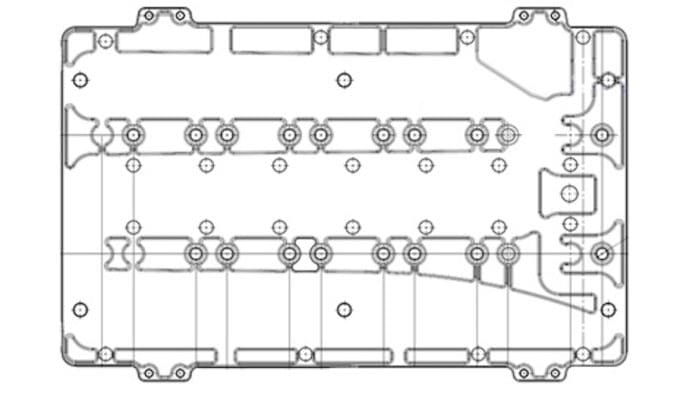

Vision Marine Technologies has partnered with Calip Group to produce custom cooling plates for its high voltage marine battery packs.

As part of the collaboration, Calip Group will supply components to enhance the thermal management of Vision Marine’s high-voltage marine battery packs.

The custom cooling plates are designed to meet marine applications, with a production line established and production set to begin in 2025.

“Overheating in a high-voltage battery designed for marine applications is a real challenge,” said Xavier Montagne, technical director of Vision Marine. “We decided to design our own specialised cooling plate to enhance pack stability and, of course, increase thermal efficiency.”

Overheating in a high-voltage battery designed for marine applications is a real challenge.

Xavier Montagne

And he explained that marine battery packs operate in environments that demand sustained, high-power delivery over extended periods.

However, most high-voltage batteries are designed to provide only brief bursts of peak power and minimal continuous output.

Marine applications can result in thermal stresses that degrade battery cells and shorten their lifespan.

To address these challenges, Vision Marine has developed cooling plates that have been adapted to the thermal requirements of marine battery packs.

By improving heat dissipation and stabilising cell temperatures, Vision Marine says these cooling plates help maintain consistent performance, enhance reliability, and extend the operational life of the cells.

Calip is among the European leaders at mastering this high-tech process.

Thierry Giorgalla

“We adapted our industrial tooling to meet the exact constraints of the battery and its specific assembly process,” said Thierry Giorgalla, general director of Calip Group.

“We’ve invested heavily in fine-tuning our FSW welding method to ensure a fully sealed cooling plate within tight tolerances. Calip is among the European leaders at mastering this high-tech process.”

Vision Marine’s battery packs feature IP67-rated stainless-steel construction, advanced thermal management systems, and modular configurations for boats from 18 to 34ft.

Calip Group’s Friction Stir Welding process has been developed to enable the precise manufacture of fully sealed cooling plates.

Vision Marine has full ownership of the tooling and strong production partnerships, and is set to scale manufacturing.

And the company says the production agreement with Calip Group is a step towards meeting growing market demand for high-performance electric boating technologies.