Cement co-processing should be used to recycle EoL composites. That’s the finding of a report commissioned by the European Boating Industry in conjunction with other industry associations.

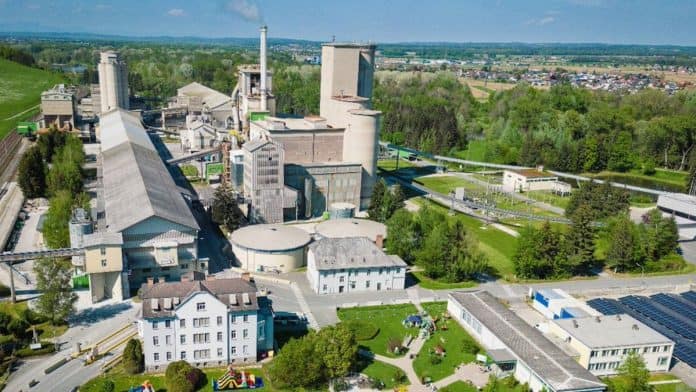

The report explored the environmental impacts of treating End-of-Life (EoL) composites by co-processing in a cement facility.

It confirms the positive environmental impact of this end-of-life solution for glass fibre reinforced thermoset composites which are used in various applications, including the automotive, construction, wind and recreational boating sectors.

The report found that each ton of EoL composite waste treated in a cement facility saves up to 1 ton of CO2 compared to traditional waste incineration methods.

The process was found to avoids emissions from waste incineration with savings varying from 560 up to 1130kg CO2 – depending on the material composition – of CO2 per ton of EoL composites. It also reduces emissions from cement production.

Virgin raw materials

In addition to CO2 savings, cement co-processing of composites was found to reduce the use of virgin raw materials by recovering the glass fibre fraction of EoL composite and there was a reduced need for fossil energy sources due to efficient recovery of the energy content from the resin fraction.

The associations are now calling on decision-makers to recognise cement co-processing as recycling process for its mineral fraction.

They say the recognition would be highly beneficial and accelerate the adoption of this existing solution to process EoL composites.

It would also foster the development of a sustainable waste collection system for EoL composites.

Having such a collection system in place will pave the way for other circular technology solutions that currently lack the necessary waste stream visibility to attract the public and private investments needed for expansion.

The life cycle assessment report was carried out by SGS INTRON and has been peer reviewed.